In today’s competitive marketplace, product packaging plays a critical role in capturing consumer attention, ensuring product safety, and supporting brand identity. Whether you’re launching a new product or re-evaluating an existing one, understanding the essential requirements of packaging is crucial. This guide will cover the five fundamental requirements of packaging, helping you create a packaging strategy that is effective, functional, and aligned with industry standards. By the end, you’ll have an in-depth understanding of what goes into making packaging that is not only visually appealing but also fully capable of protecting and preserving the product it contains.

1. Protection as a Primary Requirement

When it comes to packaging, protection is undeniably one of the most critical aspects. In a world where products travel vast distances, get handled by numerous people, and experience various environmental conditions, the right packaging can make all the difference between a product that arrives intact and one that reaches the customer damaged. Protective packaging is essential to ensure products stay safe from physical damage, contamination, and even tampering. Below, we’ll explore why protection is such a foundational packaging requirement and look at the types of materials and techniques that can help achieve it.

Why Protection is Essential in Packaging

Packaging that effectively protects a product serves several purposes. Primarily, it prevents physical damage from impacts, drops, and pressure. This is especially important for fragile items like electronics, glassware, or perishable goods, which can break or degrade without adequate protection. Furthermore, protective packaging ensures the product remains in its best condition from production to consumer purchase. Without it, businesses risk losing customers, facing returns, and experiencing a negative impact on brand reputation.

For consumable goods, protection also involves shielding products from contamination. For instance, food items, cosmetics, and pharmaceuticals often need airtight seals or specialized materials to keep out moisture, dirt, and microbes. Contaminated products not only lead to losses but can pose serious health risks to consumers.

The Essential Roles of Protective Packaging:

- Preventing Physical Damage – From dents to cracks, protective packaging ensures that products withstand rough handling.

- Reducing Contamination Risks – For consumables, proper sealing is essential to keep out contaminants.

- Mitigating Temperature Extremes – Insulated packaging helps keep temperature-sensitive items at stable temperatures during transit.

Common Protective Packaging Materials and Methods

Various materials and methods have been developed to meet the protective needs of different products. Corrugated cardboard, for example, is widely used for shipping and storage, thanks to its strength and durability. For fragile items, bubble wrap and foam inserts provide cushioning that absorbs shocks and prevents scratches or breakage. Air cushions and packing peanuts are also common, as they fill empty spaces within packaging to prevent items from moving around.

When it comes to liquids or electronics, rigid plastic cases are often used to provide a sturdy, impact-resistant barrier. Additionally, specialized packaging like molded pulp (used for eggs or electronics) can be eco-friendly while also offering high levels of protection.

Common Protective Packaging Materials and Their Uses

| Material | Best Used For | Features |

|---|---|---|

| Corrugated Cardboard | Shipping, Storage | Durable, lightweight, recyclable |

| Bubble Wrap | Fragile items | Lightweight, cushioning, flexible |

| Foam Inserts | Electronics, Glassware | Shock absorption, form-fitting |

| Air Cushions | Fillers for delicate products | Lightweight, shock-absorbing |

| Rigid Plastic Cases | Electronics, liquids | Sturdy, waterproof, tamper-resistant |

| Molded Pulp | Eco-friendly packaging solutions | Biodegradable, sturdy |

Real-Life Examples of Effective Protective Packaging

Different industries require varying levels of protection based on the product’s nature and shipping environment. For instance, the electronics industry often employs foam inserts and anti-static materials to prevent shocks and static buildup that could harm delicate circuitry. In the cosmetics industry, glass containers are often packaged with additional layers of bubble wrap or placed in protective boxes to avoid breakage during transit.

Case Study: Apple Inc.

Apple has long been praised for its thoughtful approach to protective packaging. Their products, particularly iPhones, come with form-fitted compartments inside a sturdy box that prevents movement and reduces impact. This approach not only provides excellent protection but also enhances the unboxing experience for the customer.

2. Preservation to Maintain Quality and Freshness

The second essential requirement of packaging is preservation. Preservation is critical, especially for products that are perishable or sensitive to environmental factors such as moisture, air, light, and temperature. Effective preservation not only extends the product’s shelf life but also ensures that customers receive the product in its intended quality, safety, and effectiveness.

What Preservation Entails in Packaging

Preservation in packaging is about safeguarding the product’s quality over time. For many products, exposure to air, humidity, or heat can cause degradation, leading to spoilage or reduced effectiveness. Food products are particularly susceptible to spoilage, while other products, like cosmetics or pharmaceuticals, may lose their potency if not preserved correctly. By using the right preservation methods, companies can ensure that products maintain their freshness, texture, flavor, or efficacy from production through the end of the shelf life.

The preservation element of packaging can involve:

- Reducing Oxygen Exposure – Prevents oxidation, which can spoil foods, oils, and other sensitive items.

- Controlling Moisture Levels – Prevents products from drying out or becoming overly damp.

- Shielding from Light – Protects items sensitive to UV rays, such as pharmaceuticals and certain foods.

- Temperature Control – Maintains freshness for temperature-sensitive products, like dairy or frozen foods.

Techniques and Materials Used for Product Preservation

Preservation methods vary widely, from basic sealing techniques to advanced packaging technologies. Vacuum sealing, for instance, is a popular preservation method that removes air from the package, significantly reducing the oxygen available for microbial growth and oxidation. This technique is especially effective for food items like meat, coffee, and dried goods.

Another common technique is modified atmosphere packaging (MAP), which replaces the air in a package with a controlled mixture of gases, often nitrogen or carbon dioxide, to extend the shelf life of perishable products like salads and fresh produce. This method helps reduce spoilage and maintains the product’s appearance and texture.

For liquid products, aseptic packaging is widely used in the dairy and beverage industries. This involves sterilizing both the packaging material and the product itself, allowing for a longer shelf life without refrigeration.

List of Popular Preservation Packaging Methods:

- Vacuum Sealing – Removes air to prevent oxidation and spoilage.

- Modified Atmosphere Packaging (MAP) – Controls gases to preserve freshness.

- Aseptic Packaging – Sterilizes the product and container for long shelf life.

- Refrigerated or Insulated Packaging – Maintains cold temperatures during transit.

- Desiccants and Moisture Absorbers – Protect against humidity for items like electronics or leather.

Preservation in Various Industries

Different industries leverage preservation in unique ways to meet their product needs. In the food industry, preserving freshness is essential for products like packaged salads, fresh meat, and dairy. This industry relies on refrigeration, MAP, and vacuum sealing to retain freshness and minimize waste.

In the pharmaceutical industry, preservation is critical to ensure the efficacy of drugs, which can be affected by light, temperature, and moisture. Commonly, pharmaceutical packaging includes darkened glass containers to protect against light exposure, while some medications require moisture-absorbing packets or blister packs to keep out air and humidity.

Case Study: Starbucks Ready-to-Drink Coffee

Starbucks employs aseptic packaging for its ready-to-drink coffee products. By using aseptic technology, they ensure that the coffee stays fresh for months without the need for refrigeration. This approach not only extends shelf life but also enables the product to be distributed globally without losing quality.

3. Convenience in Packaging for Enhanced User Experience

The third essential requirement in packaging design is convenience. Today’s consumers not only want high-quality products but also expect packaging that is easy to use, handle, and store. Convenience in packaging can enhance customer satisfaction, build brand loyalty, and set a product apart from its competitors.

Why Convenience Matters to Consumers

In a fast-paced world, consumers highly value convenience in packaging. The more user-friendly and intuitive a package is, the better the experience for the customer. Packaging that is easy to open, close, carry, or dispose of can have a positive impact on a consumer’s perception of a product. On the other hand, packaging that is difficult to open or use can lead to frustration, affecting the customer’s perception of the brand.

Convenient packaging is especially valued in industries like food and beverages, where consumers may prefer single-serve portions or resealable options for on-the-go consumption. Similarly, in personal care and cosmetics, easy-to-dispense packaging can enhance usability and reduce product waste. For example, resealable zippers, pull tabs, and dispensing pumps are just a few of the convenient features consumers look for in their everyday products.

Key Elements of Convenient Packaging:

- Easy Opening and Resealing – Features like zippers, peel-back lids, and tear notches enhance usability.

- Portion Control – Single-serve or pre-measured packaging appeals to consumers seeking quick solutions.

- Portability – Lightweight and compact packaging makes products easier to carry and use on the go.

- Easy Disposal – Packaging that’s easy to recycle or dispose of appeals to eco-conscious consumers.

Innovative Packaging Designs Focused on Convenience

Packaging innovation has led to a variety of designs that focus on convenience. Squeeze bottles, for example, allow consumers to dispense just the right amount of liquid without spills or mess. Flexible pouches with resealable zippers are increasingly popular in the snack and beverage markets, offering a lightweight, easy-to-store alternative to rigid containers.

Another innovative packaging type is pre-measured pods, which have become popular in the laundry and coffee industries. Pods simplify the process for consumers by providing a single-use portion that eliminates the need for measuring or handling the product directly.

Popular Convenience-Driven Packaging Examples:

- Squeeze Bottles – Used for sauces, lotions, and cleaning products, squeeze bottles provide controlled dispensing.

- Pouches with Resealable Zippers – Common in snacks, pet food, and frozen foods, these pouches allow for easy resealing.

- Single-Serve Pods – Used in coffee and laundry, pods offer pre-measured portions that save time.

- Dispensing Pumps – Common in personal care products, pumps make it easy to control product output.

How Convenience Influences Brand Perception

Convenient packaging can have a substantial impact on a brand’s perception, as consumers are likely to choose brands that make their lives easier. A positive experience with convenient packaging can create a strong, lasting impression, while a poor experience can turn customers away. In fact, studies have shown that over 70% of consumers say they are more likely to repurchase a product if they find the packaging convenient and easy to use.

Convenient packaging also encourages repeat purchases. For example, a consumer who buys a resealable snack pouch for on-the-go snacking may be more inclined to purchase that brand again due to the practical design. On the other hand, inconvenient packaging—such as items that are hard to open or spill easily—can lead to frustration and negative feedback, potentially pushing customers toward competing brands.

Case Study: Heinz Squeeze Bottle

Heinz revolutionized the condiment industry with its upside-down squeeze bottle, making it easier for consumers to dispense ketchup without waiting for the sauce to slide down the bottle. This simple, convenient design became so popular that it now dominates the condiment packaging market. Heinz’s attention to consumer convenience has made its product a household staple and strengthened brand loyalty.

4. Informational Clarity in Packaging for Consumer Awareness

The fourth essential requirement in packaging is informational clarity. Effective packaging should communicate necessary information clearly and concisely to help consumers make informed decisions. Properly displayed information can include everything from ingredients and usage instructions to safety warnings and expiry dates. This aspect is crucial for regulatory compliance, consumer safety, and enhancing trust in the brand.

Why Information on Packaging is Important

Consumers rely on packaging for important product details, especially when it comes to items that may impact their health, such as food, pharmaceuticals, and personal care products. Clear, accurate information allows consumers to understand what they are purchasing, how to use it correctly, and any potential risks. Transparency in product labeling can also strengthen consumer trust, as buyers feel confident knowing exactly what they’re getting.

Information on packaging serves several critical roles:

- Product Identification – Labeling helps consumers easily identify products, ingredients, and their intended purpose.

- Usage Instructions – Clear directions on how to use or store the product help avoid misuse and maximize product effectiveness.

- Nutritional and Allergen Information – For consumables, listing ingredients and allergens is essential for consumers with dietary restrictions.

- Legal Compliance – Many countries have stringent regulations requiring specific details on packaging to protect consumers.

Regulatory Requirements for Labeling and Information

Compliance with local and international regulations is essential for many products, particularly in the food, pharmaceutical, and chemical industries. Regulatory bodies, such as the U.S. Food and Drug Administration (FDA) and the European Union’s European Medicines Agency (EMA), enforce guidelines on product labeling and information disclosure. Failing to comply with these regulations can lead to recalls, fines, and damage to brand reputation.

Each region may have unique labeling requirements, but common elements often include:

- Product Name and Brand – Clearly states the name and brand for easy identification.

- Ingredients List – Lists all ingredients for transparency and allergy considerations.

- Expiration Date and Batch Code – Indicates freshness and aids in traceability.

- Usage and Dosage Instructions – For safe usage, particularly with health-related products.

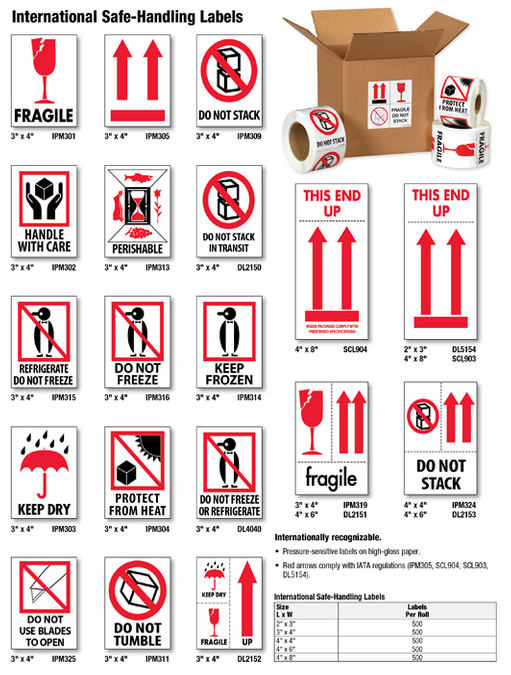

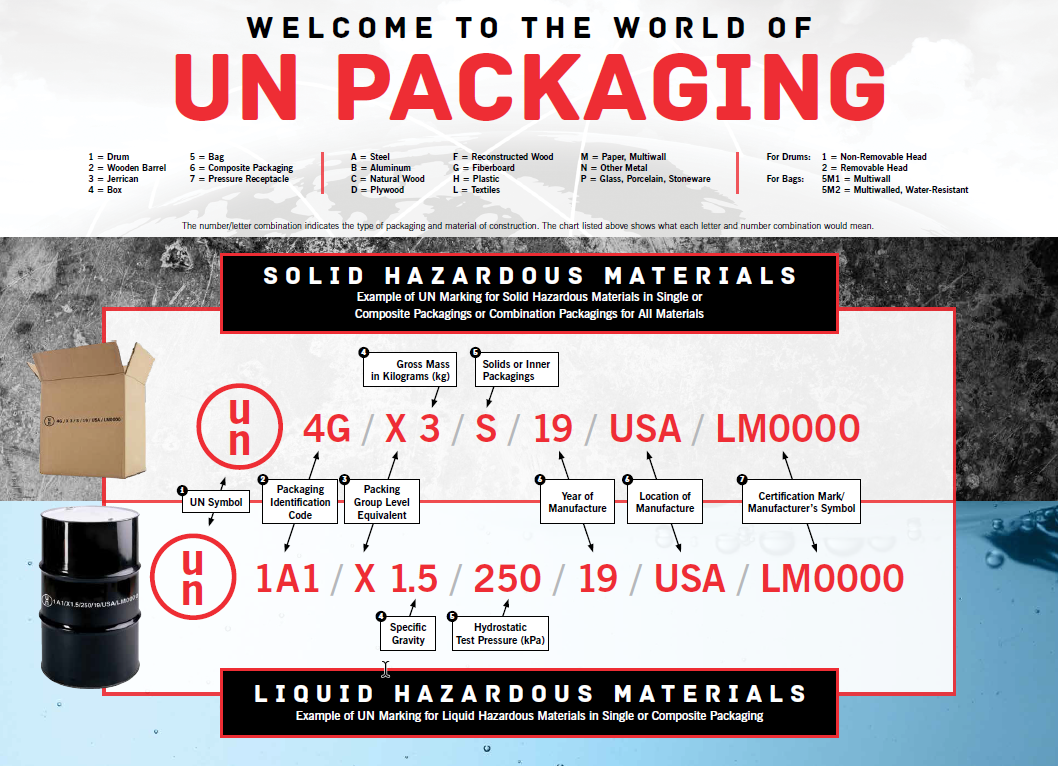

- Warning and Cautionary Labels – Required for hazardous materials or products that could pose risks.

For example, in the United States, food products must include nutrition facts, serving sizes, and a list of ingredients in descending order of weight. Similarly, pharmaceuticals must display dosage instructions, active ingredients, side effects, and proper usage guidelines. These regulations ensure consumers are well-informed, protected, and empowered to make safe choices.

Packaging Information for Different Consumer Needs

Different consumers may prioritize various types of information based on their specific needs. Health-conscious consumers, for instance, pay close attention to ingredients and nutritional details, while environmentally conscious buyers might look for information on recycling instructions and sustainable sourcing. Similarly, parents may seek additional details on child safety for products like toys, while individuals with allergies rely heavily on allergen warnings.

By understanding and addressing these diverse needs, brands can enhance their packaging to make information more accessible and useful. For example, using bold text or icons to highlight allergens or nutritional benefits can make these details easy to find. QR codes are also increasingly popular, allowing brands to provide additional information digitally, such as detailed usage guides or sourcing information, without overcrowding the packaging.

Case Study: Oatly’s Transparent Labeling

Oatly, a popular plant-based milk brand, emphasizes transparency in its packaging by displaying a straightforward ingredients list and clear nutritional information on each carton. Additionally, the brand includes messages about its environmental impact and sustainability practices, aligning with the values of its eco-conscious consumer base. This clear and informative approach has helped Oatly build a strong brand identity centered around trust and transparency.

5. Sustainability as a Modern Requirement of Packaging

The fifth essential requirement of packaging is sustainability. As environmental awareness continues to grow, consumers are increasingly seeking brands that prioritize eco-friendly packaging solutions. Sustainable packaging not only appeals to eco-conscious consumers but also helps reduce environmental impact, conserving resources and minimizing waste.

Growing Importance of Eco-Friendly Packaging

With rising concerns over climate change, plastic pollution, and resource scarcity, sustainable packaging has shifted from a trend to a necessity. Today, consumers are more mindful of their environmental footprint and actively look for products packaged in environmentally responsible ways. Research shows that over 60% of consumers prefer brands that use sustainable packaging, and many are even willing to pay a premium for it.

Sustainable packaging focuses on using materials that have a reduced impact on the environment, both in terms of production and end-of-life disposal. This often includes renewable, recyclable, or compostable materials that break down more easily than traditional plastics. Additionally, sustainable packaging can improve a company’s brand reputation by showing a commitment to social responsibility, often leading to increased customer loyalty.

Benefits of Sustainable Packaging:

- Reduces Waste – Helps minimize landfill contributions by using recyclable or compostable materials.

- Conserves Resources – Uses renewable resources, reducing dependence on non-renewable materials like plastics.

- Improves Brand Image – Appeals to eco-conscious consumers, enhancing brand reputation.

- Encourages Innovation – Drives companies to explore creative solutions and innovative materials.

Examples of Sustainable Packaging Materials and Practices

Numerous materials and practices have been developed to support sustainable packaging goals. Recycled paper and cardboard, for example, are widely used for packaging boxes and fillers, offering both strength and environmental friendliness. Additionally, biodegradable plastics, made from materials like cornstarch or sugarcane, offer an alternative to conventional plastics that can break down naturally over time.

Other sustainable options include compostable materials that decompose in composting facilities, leaving behind no harmful residue. Some companies are also exploring plant-based plastics (bioplastics) and reusable packaging solutions to further reduce waste. Beyond materials, sustainable packaging can also involve practices like minimalistic packaging design, which reduces unnecessary materials and lowers overall waste.

Common Sustainable Packaging Materials and Their Benefits

| Material | Characteristics | Benefits |

|---|---|---|

| Recycled Paper/Cardboard | Strong, recyclable, versatile | Reduces demand for virgin paper |

| Biodegradable Plastics | Made from plant-based sources, decomposable | Breaks down naturally over time |

| Compostable Materials | Decomposes fully in composting environments | Leaves no harmful residue |

| Plant-Based Plastics | Derived from plants, can be compostable | Lowers carbon footprint |

| Glass and Aluminum | Recyclable, reusable | Long lifespan, reduces landfill |

| Reusable Packaging | Designed for multiple uses | Reduces need for single-use items |

How to Incorporate Sustainability Without Compromising Other Requirements

One of the biggest challenges companies face is balancing sustainability with other packaging requirements like protection, preservation, and convenience. For instance, switching to biodegradable materials may be more sustainable but could compromise product protection if not done carefully. Similarly, while using less packaging is eco-friendly, it should still provide sufficient convenience and usability for the customer.

To achieve this balance, brands can opt for hybrid packaging solutions that combine eco-friendly materials with durable protection. For example, using recycled cardboard with protective inserts can ensure both sustainability and product safety. In addition, companies are investing in innovative designs, like refillable containers, which allow consumers to purchase refills instead of disposing of packaging after a single use. By carefully considering each packaging requirement, brands can adopt sustainable practices without sacrificing quality or functionality.

Examples of Brands Leading in Sustainable Packaging

Many well-known brands are taking strides in sustainable packaging. IKEA, for instance, has committed to phasing out all single-use plastic in its packaging, instead opting for renewable or recyclable materials. In the beverage industry, Coca-Cola has introduced a fully recyclable bottle made from 100% recycled plastic, aiming to reduce its environmental footprint. Lush Cosmetics is another leader, using minimal or “naked” packaging for many of its products, and even offering packaging-free items to eliminate waste altogether.

Case Study: Patagonia’s Sustainable Packaging

Patagonia, an outdoor clothing and gear brand, has integrated sustainable packaging practices across its product lines. They use recycled cardboard for shipping boxes, compostable garment bags, and minimal packaging overall. This approach aligns with Patagonia’s environmental ethos, appealing to eco-conscious consumers and reinforcing the brand’s commitment to protecting the planet.